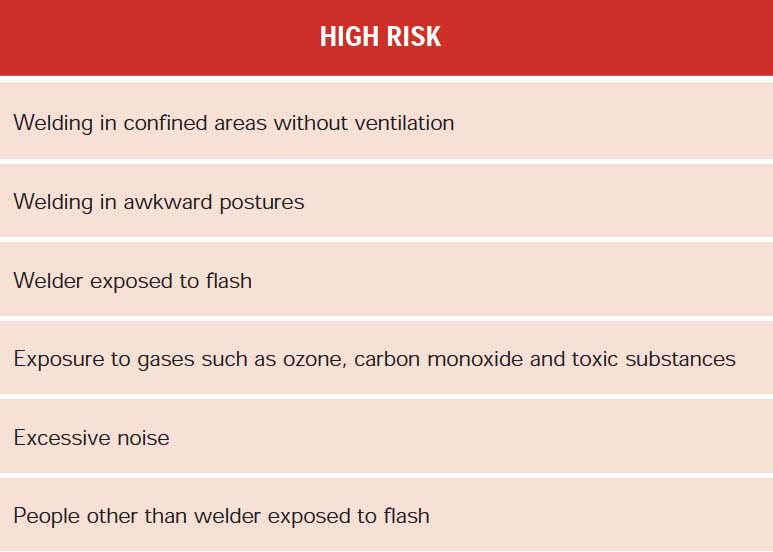

Welding safety starts with an understanding of what could go wrong, and preparation for when it does.

Risks include electric shock, injuries related in inhalation of toxic fumes, eye injury, and skin burns.

To start, protective clothing and equipment must be worn during all welding operations including helmets and shields.

For arc welding, the electric arc is a very powerful source of light, including visible, ultraviolet, and infrared.

During all electric welding processes, operators must use safety goggles and a hand shield or helmet equipped with a suitable filter glass to protect against the intense ultraviolet and infrared rays.

When others are in the vicinity of the electric welding processes, the area must be screened so the arc cannot be seen either directly or by reflection from glass or metal.

During all oxyacetylene welding and cutting processes, operators must use safety goggles to protect the eyes from heat, glare, and flying fragments of hot metals.

Also be sure to keep MSDS sheets (Material Safety Data Sheets) for all hazardous materials. Every manufacturer provides MSDS sheets to keep you informed regarding any potential hazards, such as if a respirator is needed when working on a project.

Overview

Welding safety starts with having the right protective gear. This includes:

- Respirator/Welders Mask: There are multiple types of respirators. Buy the one that is made for welders and the type of projects you will be performing. If purchasing a mask with a filter, match the filter to the types of metals and coatings used.

- Keep the area clean and check any gasses for signs of leaks.

- Ventilation: All welding areas should have proper ventilation. Check with OSHA for the up-to-date standards. Poor ventilation leads to “plume poisoning”. If you suspect that be inhaled a toxic plume seek medical help immediately.

- Storage: All flammables should be stored in a flammable liquids locker.

- Eye protection: welding eye protection protects against injuries from debris and from the effects of ultraviolet light. Different types of helmets are made to protect you when performing different types of welding. These vary by shade number, having a passive or auto-darkening lens (automatically adjusts to welding rays) and comfort/fit.

- Fire protection: Sparks created during the welding process can start fires. For welding, Class C extinguishers are often used since these are for electrical fires. Sand and water can also help to extinguish fires.

- Protective Clothing: All skin areas need to be protected to protect against molten metal and sparks. This includes:

-

- Long sleeve shirts

- Pants that cover the tops of shoes

- Gloves

- Shoes or boots

- Hair is protected with something called a welders beanie

- Leather jackets are also effective for protection from slag and sparks

- Leather aprons provide some protection when sitting down

- Shoe covers called spats protect shoes, something helpful if you are working on a project that produces sparks and slag (molten metal)

Welding Safety Tip: Use pliers when handling metals. If you believe a metal is cool, use the back of the hand and slowing bring it closer to the metal. You’ll feel the heat as you get closer if it is too hot to handle.

- Prepare for Accidents: Keep a first aid kit on hand that includes bandages and burn spray. Consider an option that exceeds ANSI (American National Standards Institute) and OSHA guidelines such as a first aid kit.

Helmets and Shields

Welding arcs are intensely brilliant lights. They contain a proportion of ultraviolet light which may cause eye damage.

For this reason, the arc should never be viewed with the naked eye within a distance of 50.0 ft (15.2 m).

The brilliance and exact spectrum, and therefore the danger of the light, depends on the welding process, the metals in the arc, the arc atmosphere, the length of the arc, and the welding current.

Operators, fitters, and those working nearby need protection against arc radiation.

The intensity of the light from the arc increases with increasing current and arc voltage. Arc radiation, like all light radiation, decreases with the square of the distance.

Those processes that produce smoke surrounding the arc have a less bright arc since the smoke acts as a filter.

The spectrum of the welding arc is similar to that of the sun. Exposure of the skin and eyes to the arc is the same as exposure to the sun.

Being closest, the welder needs a helmet to protect his eyes and face from harmful light and particles of hot metal.

The welding helmet is generally constructed of a pressed fiber insulating material. It has an adjustable headband that makes it usable by persons with different head sizes.

To minimize reflection and glare produced by the intense light, the helmet is dull black in color.

It fits over the head and can be swung upward when not welding. The chief advantage of the helmet is that it leaves both hands free, making it possible to hold the work and weld at the same time.

The hand-held shield provides the same protection as the helmet but is held in position by the handle. This type of shield is frequently used by an observer or a person who welds for a short period of time.

The protective welding helmet has lens holders used to insert the cover glass and the filter glass or plate. The standard size for the filter plate is 2 x 4-1/4 in. (50 x 108 mm). In some helmets lens holders open or flip upwards.

Lenses are designed to prevent flash burns and eye damage by absorption of the infrared and ultraviolet rays produced by the arc.

The filter glasses or plates come in various optical densities to filter out various light intensities, depending on the welding process, type of base metal, and the welding current.

The color of the lens, usually green, blue, or brown, is an added protection against the intensity of white light or glare.

Colored lenses make it possible to clearly see the metal and weld. A magnifier lens placed behind the filter glass is sometimes used to provide clear vision.

A cover plate should be placed outside the filter glass to protect it from weld spatter.

The filter glass must be tempered so that is will not break if hit by flying weld spatter.

Filter glasses must be marked showing the manufacturer, the shade number, and the letter “H’ indicating it has been treated for impact resistance.

Gas Metal-Arc Welding Helmets

Gas metal-arc (MIG) welding safety requires darker filter lenses than shielded metal-arc (stick) welding.

The intensity of the ultraviolet radiation emitted during gas metal-arc welding ranges from 5 to 30 times brighter than welding with covered electrodes.

Do not weld with cracked or defective shields because penetrating rays from the arc may cause serious burns.

Be sure that the colored glass plates are the proper shade for arc welding. Protect the colored glass plate from molten metal spatter by using a cover glass.

Replace the cover glass when damaged or spotted by molten metal spatter.

Face shields must also be worn where required to protect eyes. Welders must wear safety glasses and chippers and grinders often use face shields in addition to safety glasses.

In some welding operations, the use of mask-type respirators is required.

Helmets with the “bubble” front design can be adapted for use with respirators.

See our page on arc welding safety for helmet lens and plate thickness by application tables.

Safety Goggles

During all-electric welding processes, operators must wear safety goggles.

Safety goggles protect your eyes from weld spatter which occasionally gets inside the helmet.

These clear goggles also protect the eyes from slag particles when chipping and hot sparks when using an angle grinder.

Contact lenses should not be worn when welding or working around welders.

Tinted safety glasses with side shields are recommended, especially when welders are chipping or grinding. Those working around welders should also wear tinted safety glasses with side shields.

Protective Clothing

Personnel exposed to the hazards created by welding, cutting, or brazing operations shall be protected by personal protective equipment in accordance with OSHA standards, Subpart I, Personal Protective Equipment, paragraph 1910.132.

The appropriate protective clothing required for any welding operation will vary with the size, nature, and location of the work to be performed.

Welders should wear work or shop clothes without openings or gaps to prevent arc rays from contacting the skin.

Those working close to arc welding should also wear protective clothing. Clothing should always be kept dry, including gloves.

Woolen clothing should be worn instead of cotton since wool is not easily burned or damaged by weld spatter and helps to protect the welder from changes in temperature.

Cotton clothing, if used, should be chemically treated to reduce its combustibility.

All other clothing, such as jumpers or overalls, should be reasonably free from oil or grease.

Flameproof aprons or welding jackets made of leather, fire-resistant material, or other suitable material should be worn for protection against spatter of molten metal, radiated heat, and sparks.

Capes or shoulder covers made of leather or other suitable materials should be worn during overhead welding or cutting operations.

Leather skull caps may be worn under helmets to prevent head burns.

Sparks may lodge in rolled-up sleeves, pockets of clothing, or cuffs of overalls and trousers. Therefore, sleeves and collars should be kept buttoned and pockets should be eliminated from the front of overalls and aprons. Alternatively, you should invest in a good pair of welding sleeves to make sure you are properly protected.

Trousers and overalls should not be turned up on the outside. For heavy work, fire-resistant leggings, high boots, or other equivalent means should be used.

In production work welding safety, a sheet metal screen in front of the worker´s legs can provide further protection against sparks and molten metal in cutting operations.

Flameproof welding gloves, preferably of leather, should be worn to protect the hands and arms from rays of the arc, molten metal spatter, sparks, and hot metal.

Leather gloves should be of sufficient thickness so that they will not shrivel from the heat, burn through, or wear out quickly.

Leather gloves should not be used to pick up hot items, since this causes the leather to become stiff and crack.

Do not allow oil or grease to come in contact with the gloves as this will reduce their flame resistance and cause them to be readily ignited or charred.

Protective Equipment

Protective equipment is at the heart of any welding safety plan. Where there is exposure to sharp or heavy falling objects or a hazard of bumping in confined spaces, hard hats or head protectors must be used.

For welding and cutting overhead or in confined spaces, steel-toed boots and ear protection must also be used. If you are going to be welding down low, then welding knee pads are recommended.

For welding safety in any area, the operation should be adequately screened to protect nearby workers or passers-by froman the glare of welding.

The screens should be arranged so that no serious restriction of ventilation exists. The screens should be mounted so that they are about 2.0 ft above the floor unless the work is performed at such a low level that the screen must be extended closer to the floor to protect adjacent workers.

The height of the screen is normally 6.0 ft (1.8 m) but may be higher depending upon the situation.

Screen and surrounding areas must be painted with special paints that absorb ultraviolet radiation yet do not create high contrast between the bright and dark areas.

Light pastel colors of a zinc or titanium dioxide base paint are recommended. Black paint should not be used.

Related: The Essential Welding Tool List

Fire Hazards

The fire prevention welding safety and protection plan is the responsibility of welders, cutters, and supervisors.

Approximately six percent of the fires in industrial plants are caused by cutting and welding which has been done primarily with portable equipment or in areas not specifically designated for such work.

The elaboration of basic precautions to be taken for fire prevention during welding or cutting is found in the Standard for Fire Prevention in Use of Cutting and Welding Processes, National Fire Protection Association Standard 51B, 1962.

Some of the basic welding safety precautions for fire prevention in welding or cutting work are given below.

During the welding and cutting operations, sparks and molten spatter are formal which sometimes fly considerable distances.

Sparks have also fallen through cracks, pipe holes, or other small openings in floors and partitions, starting fires in other areas which temporarily may go unnoticed.

For these reasons, welding or cutting should not be done near flammable materials unless every precaution is taken to prevent ignition.

Hot pieces of base metal may come in contact with combustible materials and start fires.

Fires and explosions have also been caused when heat is transmitted through walls of containers to flammable atmospheres or to combustibles within containers.

Anything that is combustible or flammable is susceptible to ignition by cutting and welding.

When welding or cutting parts of vehicles, the oil pan, gasoline tank, and other parts of the vehicle are considered fire hazards and must be removed or effectively shielded from sparks, slag, and molten metal.

Whenever possible, flammable materials attached to or near equipment requiring welding, brazing, or cutting will be removed. If removal is not practical, a suitable shield of heat-resistant material should be used to protect the flammable material.

Fire extinguishing equipment, for any type of fire that may be encountered, must be present.

Safety When Welding in Confined Space

Welding safety in confined spaces has its own set of challenges. A confined space is intended to mean a relatively small or restricted space such as a tank, boiler, pressure vessel, or small compartment of a ship or tank.

When welding or cutting is being performed in any confined space, the gas cylinders and welding machines shall be left on the outside. Before operations are started, heavy portable equipment mounted on wheels shall be securely blocked to prevent accidental movement.

Where a welder must enter a confined space through a manhole or other all opening, means will be provided for quickly removing him in case of emergency. When safety belts and lifelines are used for this purpose, they will be attached to the welder´s body so that he cannot be jammed in a small exit opening.

An attendant with a preplanned rescue procedure will be stationed outside to observe the welder at all times and be capable of putting rescue operations into effect.

When arc welding is suspended for any substantial period of time, such as during lunch or overnight, all electrodes will be removed from the holders with the holders carefully located so that accidental contact cannot occur.

The welding machines will be disconnected from the power source.

In order to eliminate the possibility of gas escaping through leaks or improperly closed valves when gas welding or cutting, the gas and oxygen supply valves will be closed, the regulators released, the gas and oxygen lines bled, and the valves on the torch shut off when the equipment will not be used for a substantial period of time.

Where practical, the torch and hose will also be removed from the confined space.

After welding operations are completed, the welder will mark the hot metal or provide some other means of warning other workers.

See our guide to metal fabrication safety for more information.