An electrode is a metal wire that is coated.

It is made out of materials with a similar composition to the metal being welded.

There are a variety of factors that go into choosing the right electrode for each project. In summary:

- SMAW or stick electrodes are consumable, meaning they become part of the weld and are also referred to as a filler electrode or welding rod.

- TIG tungsten electrodes are non-consumable as they do not melt and become part of the weld, requiring the use of a welding rod.

- TIG filler rods are an optional filler material used to fuse two pieces of stock together as a composite.

- The MIG welding electrode is a continuously fed wire referred to as MIG wire.

Electrode selection is critical to ease of cleanup, weld strength, bead quality, and minimizing any spatter.

Electrodes need to be stored in a moisture-free environment and carefully removed from any package (follow the directions to avoid damage).

Covered Welding Electrodes

When molten metal is exposed to air, it absorbs oxygen and nitrogen and becomes brittle or is otherwise adversely affected.

A slag cover is needed to protect molten or to solidify weld metal from the atmosphere. This cover can be obtained from the electrode coating.

The composition of the welding electrode coating determines its usability, the composition of the deposited weld metal, and the electrode specification.

The formulation of welding electrode coatings is based on well-established principles of metallurgy, chemistry, and physics.

The coating protects the metal from damage, stabilizes the arc, and improves the weld in other ways, which include:

- Smooth weld metal surface with even edges

- Minimum spatter adjacent to the weld

- A stable welding arc

- Penetration control

- A strong, tough coating

- Easier slag removal

- Improved deposition rate

The metal-arc electrodes may be grouped and classified as bare or thinly coated electrodes and shielded arc or heavy coated electrodes.

The covered electrode is the most popular type of filler metal used in arc welding.

The composition of the electrode covering determines the usability of the electrode, the composition of the deposited weld metal, and the specification of the electrode.

The type of electrode used depends on the specific properties required in the weld deposited.

These include corrosion resistance, ductility, high tensile strength, the type of base metal to be welded, the position of the weld (flat, horizontal, vertical, or overhead), and the type of current and polarity required.

Classification

The welding industry has adopted the American Welding Society’s classification number series for welding rod electrodes.

The electrode identification system for steel arc welding is set up as follows:

- E – indicates electrode for arc welding.

- The first two (or three) digits – indicate tensile strength (the resistance of the material to forces trying to pull it apart) in thousands of pounds per square inch of the deposited metal.

- The third (or fourth) digit – indicates the position of the weld. 0 indicates the classification is not used; 1 is for all positions; 2 is for flat and horizontal positions only; 3 is for flat position only.

- The fourth (or fifth) digit – indicates the type of electrode coating and the type of power supply used; alternating or direct current, straight or reverse polarity.

- The types of coating, welding current, and polarity position designated by the fourth (or fifth) identifying digit of the electrode classification are listed in Tables 5-4 below.

The number E6010 – indicates an arc welding electrode with minimum stress relieved tensile strength of 60,000 psi; is used in all positions, and reverse polarity direct current is required.

Coating, Current and Polarity Types Designated By the Fourth Digit in the Electrode Classification Number

| Digit | Coating | Weld Current |

|---|---|---|

| 0 | * | * |

| 1 | Cellulose Potassium | ac, dcrp, dcsp |

| 2 | Titania sodium | ac, dcsp |

| 3 | Titania potassium | ac, dcsp, dcrp |

| 4 | Iron Powder Titania | ac, dcsp, dcrp |

| 5 | Low hydrogen sodium | dcrp |

| 6 | Low hydrogen potassium | ac, dcrp |

| 7 | Iron powder iron oxide | ac, dcsp |

| 8 | Iron powder low hydrogen | ac, dcrp, dcsp |

When the fourth (or last) digit is 0, the type of coating and current to be used is determined by the third digit.

Table 5-4

The welding rod electrode identification system for SMAW stainless steel is set up as follows:

- E indicates electrode for arc welding.

- The first three digits indicated the American Iron and Steel-type of stainless steel.

- The last two digits indicate the current and position used.

- The number E-308-16 by this system indicates stainless steel Institute type 308; used in all positions; with alternating or reverse polarity direct current.

Classification System for Submerged Arc Electrodes

The system for identifying solid bare carbon steel for the submerged arc is as follows:

- The prefix letter E is used to indicate an electrode. This is followed by a letter that indicates the level of manganese, i.e., L for low, M for medium, and H for high manganese. This is followed by a number of the average amount of carbon in points or hundredths of a percent. The composition of some of these wires is almost identical to some of the wires in the gas metal arc welding specification.

- The electrode wires used for submerged arc welding are given in the American Welding Society specification, “Bare Mild Steel Electrodes and Fluxes for Submerged Arc Welding.” This specification provides both the wire composition and the weld deposit chemistry based on the flux used. The specification does give the composition of the electrode wires. This information is given in table 8-1. When these electrodes are used with specific submerged arc fluxes and welded with proper procedures, the deposited weld metal will meet the mechanical properties required by the specification.

- In the filler reds used for oxyfuel gas welding, the prefix letter is R, followed by a G indicating that the rod is used expressly for gas welding. These letters are followed by two digits which will be 45, 60, or 65. These designate the approximate tensile strength in 1000 psi (6895 kPa).

- In nonferrous filler metals, the prefix E, R, or RB is used, followed by the chemical symbol of the principal metals in the wire. The initials for one or two elements will follow. If there is more than one alloy containing the same elements, a suffix letter or number may be added.

- The American Welding Society’s specifications are most widely used for specifying bare welding rod and electrode wires. There are also military specifications such as the MIL-E or -R types and federal specifications, normally the QQ-R type and AMS specifications. The particular specification involved should be used for specifying filler metals.

The most important aspect of solid welding electrode wires and rods is their composition, given by the specification. The specifications provide the limits of composition for the different wires and mechanical property requirements.

Occasionally, on copper-plated solid wires, the copper may flake off in the feed roll mechanism and create problems. It may plug liners or contact tips. A light copper coating is desirable. The electrode wire surface should be reasonably free of dirt and drawing compounds. This can be checked by using a white cleaning tissue and pulling a length of wire through it. Too much dirt will clog the liners, reduce current pickup in the tip, and may create erratic welding operations.

The temper or strength of the wire can be checked in a testing machine. Wire of a higher strength will feed through guns and cables better. The minimum tensile strength recommended by the specification is 140,000 psi (965,300 kPa).

The continuous electrode wire is available in many different packages. They range from tiny spools used on spool guns to medium-size spools for fine-wire gas metal arc welding. Coils of electrode wire are available, which can be placed on reels that are a part of the welding equipment. There are also huge reels weighing many hundreds of pounds. The electrode wire is also available in drums or payoff packs where the wire is laid in the round container and pulled from the container by an automatic wire feeder.

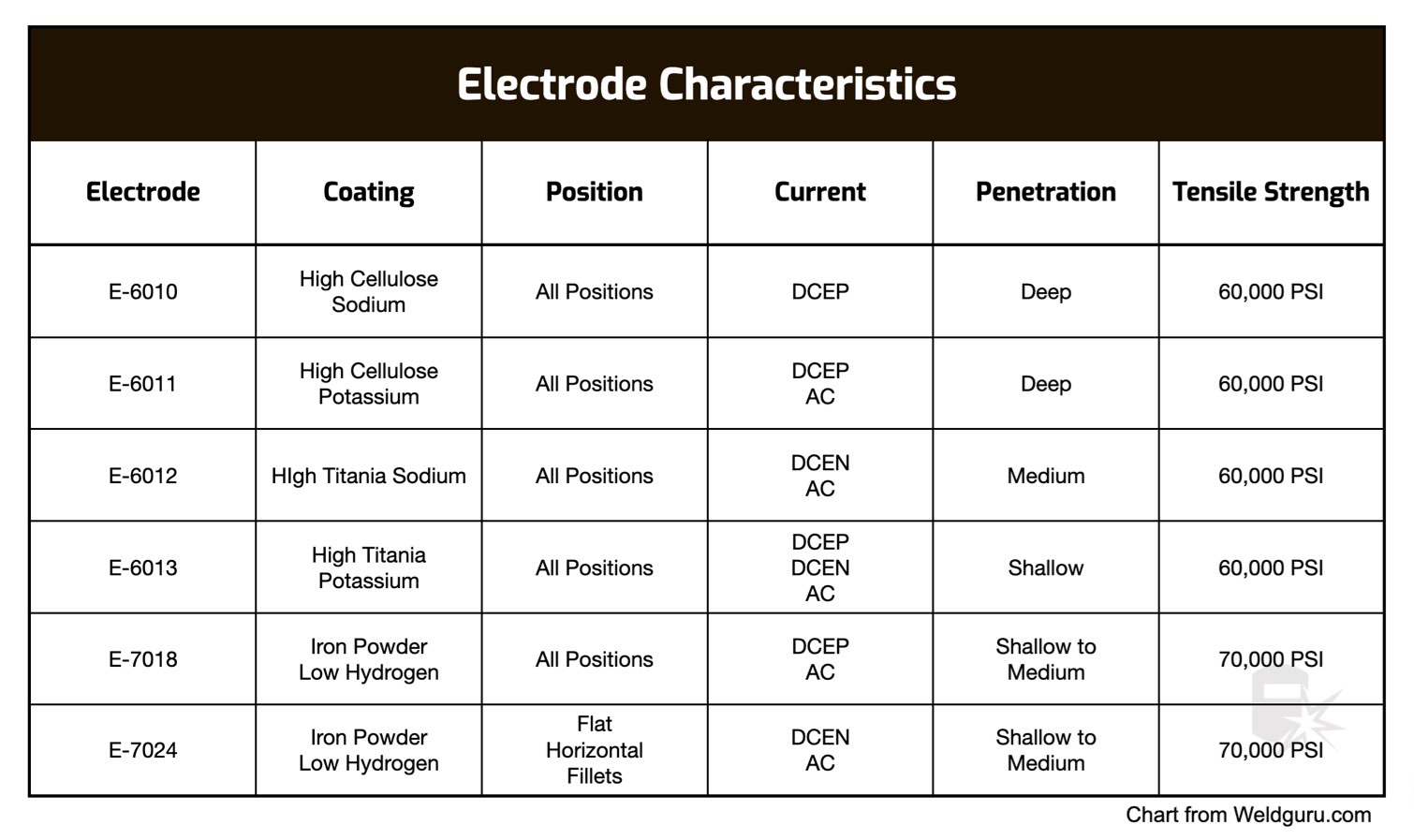

Here’s a chart that describes six standard electrodes used for welding mild steel:

Coatings

The coatings of welding electrodes for welding mild and low alloy steels may have from 6 to 12 ingredients, which includes:

- Cellulose – to provide a gaseous shield with a reducing agent in which the disintegration of cellulose produces the gas shield surrounding the arc

- Metal carbonates – to adjust the basicity of the slag and to provide a reducing atmosphere

- Titanium dioxide – to help form a highly fluid but quick-freezing slag and to provide ionization for the arc

- Ferromanganese & ferrosilicon – to help deoxidize the molten weld metal and supplement the manganese content and silicon content of the deposited weld metal.

- Clays & gums – to provide elasticity for extruding the plastic coating material and to help provide strength to the coating

- Calcium fluoride – to provide shielding gas to protect the arc, adjust the basicity of the slag, and provide fluidity and solubility of the metal oxides

- Mineral silicates – to provide slag and give strength to the electrode covering

- Alloying metals including nickel, molybdenum, and chromium – to provide alloy content to the deposited weld metal

- Iron or manganese oxide – to adjust the slag’s fluidity and properties and help stabilize the arc.

- Iron powder – to increase productivity by providing extra metal to be deposited in the weld.

The principal types of welding electrode coatings for mild steel and are described below.

- Cellulose-sodium (EXX10): Electrodes of this type of cellulosic material in the form of wood flour or reprocessed low alloy electrodes have up to 30 percent paper. The gas shield contains carbon dioxide and hydrogen, which are reducing agents. These gases tend to produce a digging arc that provides deep penetration. The weld deposit is somewhat rough, and the spatter is at a higher level than other electrodes. It does provide excellent mechanical properties, particularly after aging. This is one of the earliest types of electrodes developed and is widely used for cross-country pipelines using the downhill welding technique. It is normally used with direct current with the electrode positive (reverse polarity).

- Cellulose-potassium (EXX11): This electrode is very similar to the cellulose-sodium electrode, except more potassium is used than sodium. This provides ionization of the arc and makes the electrode suitable for welding with alternating current. The arc action, the penetration, and the weld results are very similar. In both E6010 and E6011 electrodes, small amounts of iron powder may be added. This assists in arc stabilization and will slightly increase the deposition rate.

- Rutile-sodium (EXX12): When rutile or titanium dioxide content is relatively high with respect to the other components, the electrode will be especially appealing to the welder. Electrodes with this coating have a quiet arc, an easily controlled slag, and a low level of spatter. The weld deposit will have a smooth surface, and the penetration will be less than with the cellulose electrode. The weld metal properties will be slightly lower than the cellulosic types. This type of electrode provides a fairly high rate of deposition. It has a relatively low arc voltage and can be used with alternating current or direct current with a negative electrode (straight polarity).

- Rutile-potassium (EXX13): This electrode coating is very similar to the rutile-sodium type, except that potassium is used to provide arc ionization. This makes it more suitable for welding with alternating current. It can also be used with direct current with either polarity. It produces a very quiet, smooth-running arc, making it great as an all-round rod.

- Rutile-iron powder (EXXX4): This coating is very similar to the rutile coatings mentioned above, except that iron powder is added. If iron content is 25 to 40 percent, the electrode is EXX14. If iron content is 50 percent or more, the electrode is EXX24. With the lower percentage of iron powder, the electrode can be used in all positions. The higher percentage of iron paler can only be used in the flat position or for making horizontal fillet welds. In both cases, the deposition rate is increased based on the amount of iron powder in the coating.

- Low hydrogen-sodium (EXXX5): Coatings that contain a high proportion of calcium carbonate or calcium fluoride are called low hydrogen, lime ferritic, or basic type electrodes. In this coating class, cellulose, clays, asbestos, and other minerals containing combined water are not used. This is to ensure the lowest possible hydrogen content in the arc atmosphere. These electrode coatings are baked at a higher temperature. The low hydrogen electrode family has superior weld metal properties. They provide the highest ductility of any of the deposits. These electrodes have a medium arc with medium or moderate penetration. They have a medium speed of deposition but require special welding techniques for the best results. Low hydrogen electrodes must be stored under controlled conditions. This type is normally used with direct current with electrode positive (reverse polarity).

- Low hydrogen-potassium (EXXX6): This type of coating is similar to the low hydrogen-sodium, except for the substitution of potassium for sodium to provide arc ionization. This electrode is used with alternating current and can be used with direct current, electrode positive (reverse polarity). The arc action is smoother, but the penetration of the two electrodes is similar.

- Low hydrogen-potassium (EXXX6): The coatings in this class of electrodes are similar to the low-hydrogen type mentioned above. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an EXX18.

- Low hydrogen-iron powder (EXX28): This electrode is similar to the EXX18 but has 50 percent or more iron powder in the coating. It is usable only when welding in the flat position or for making horizontal fillet welds. The deposition rate is higher than EXX18. Low hydrogen coatings are used for all of the higher-alloy electrodes. By adding specific metals in the coatings, these electrodes become the alloy types where suffix letters are used to indicate weld metal compositions. Electrodes for welding stainless steel are also the low-hydrogen type.

- Iron oxide-sodium (EXX20): Coatings with high iron oxide content produce a weld deposit with a large amount of slag. This can be difficult to control. This coating type produces high-speed deposition and provides medium penetration with a low spatter level. The resulting weld has a very smooth finish. The electrode is usable only with flat position welding and for making horizontal fillet welds. The electrode can be used with alternating current or direct current with either polarity.

- Iron-oxide-iron power (EXX27): This type of electrode is very similar to the iron oxide-sodium type, except it contains 50 percent or more iron power. The increased amount of iron power greatly increases the deposition rate. It may be used with an alternating direct current of either polarity.

There are many types of coatings other than those mentioned here, most of which are usually combinations of these types but for special applications such as hard surfacing, cast iron welding, and nonferrous metals.

Related read: 6010 vs 6011 vs 6013 vs 7018 vs 7024

Storage

Electrodes must be kept dry. Moisture destroys the desirable characteristics of the coating and may cause excessive spattering and lead to porosity and cracks in the formation of the welded area. Electrodes exposed to damp air for more than two or three hours should be dried by heating in a suitable oven (fig 5-32) for two hours at 500°F (260°C).

After they have dried, they should be stored in a moisture-proof container. Bending the electrode can cause the coating to break loose from the core wire. Electrodes should not be used if the core wire is exposed.

Electrodes that have an “R” suffix in the AWS classification have a higher moisture resistance.

The Types of Electrodes

Bare Electrodes

Bare welding electrodes are made of wire compositions required for specific applications.

These electrodes have no coatings other than those required in wire drawing. These wire drawing coatings have some slight stabilizing effect on the arc but are otherwise of no consequence. Bare electrodes are used to weld manganese steel and other purposes where a coated electrode is not required or undesirable. A diagram of the transfer of metal across the arc of a bare electrode is shown in figure 5-29.

Light Coated Electrodes

Light coated welding electrodes have a definite composition.

A light coating has been applied on the surface by washing, dipping, brushing, spraying, tumbling, or wiping. The coatings improve the characteristics of the arc stream. They are listed under the E45 series in the electrode identification system.

The coating generally serves the functions described below:

- It dissolves or reduces impurities such as oxides, sulfur, and phosphorus.

- It changes the surface tension of the molten metal so that the globules of metal leaving the end of the electrode are smaller and more frequent. This helps make the flow of molten metal more uniform.

- It increases the arc stability by introducing materials readily ionized (i.e., changed into small particles with an electric charge) into the arc stream.

- Some of the light coatings may produce a slag. The slag is quite thin and does not act in the same manner as the shielded arc electrode type slag.

Shielded Arc or Heavy Coated Electrodes

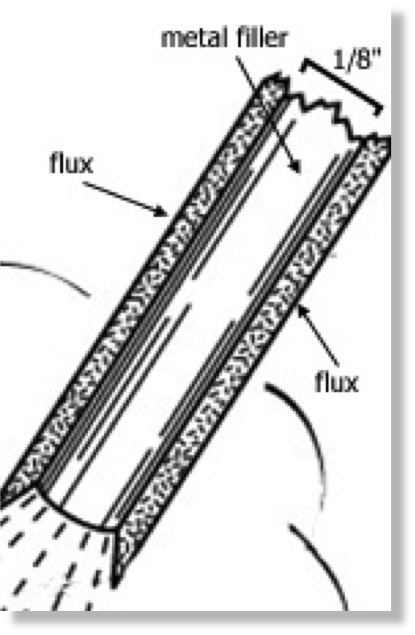

Shielded arc or heavy coated welding electrodes have a definite composition on which a coating has been applied by dipping or extrusion.

The electrodes are manufactured in three general types:

- those with cellulose coatings

- those with mineral coatings

- those whose coatings are combinations of mineral and cellulose

The cellulose coatings are composed of soluble cotton or other forms of cellulose with small amounts of potassium, sodium, or titanium, and in some cases, added minerals.

The mineral coatings consist of sodium silicate, metallic oxides, clay, and other inorganic substances or combinations.

Cellulose-coated electrodes protect the molten metal with a gaseous zone around the arc and the weld zone.

The mineral-coated electrode forms a slag deposit.

The shielded arc or heavy coated electrodes are used for welding steels, cast iron, and hard surfacing. See figure 5-31 below.

Functions of Shielded Arc or Heavy Coated Electrodes

These welding electrodes produce a reducing gas shield around the arc.

This prevents atmospheric oxygen or nitrogen from contaminating the weld metal.

The oxygen readily combines with the molten metal, removing alloying elements and causing porosity.

Nitrogen causes brittleness, low ductility, and in some cases, low strength and poor corrosion resistance.

They reduce impurities such as oxides, sulfur, and phosphorus so that these impurities will not impair the weld deposit.

They provide substances to the arc, which increases its stability. This eliminates wide fluctuations in the voltage so that the arc can be maintained without excessive spattering.

By reducing the attractive force between the molten metal and the end of the electrodes or by reducing the surface tension of the molten metal, the vaporized and melted coating causes the molten metal at the end of the electrode to break up into fine, small particles.

The coatings contain silicates which will form a slag over the molten weld and base metal. Since the slag solidifies at a relatively slow rate, it holds the heat and allows the underlying metal to cool and solidify slowly. This slow solidification of the metal eliminates the entrapment of gases within the weld and permits solid impurities to float to the surface. Slow cooling also has an annealing effect on the weld deposit.

The physical characteristics of the weld deposit are modified by incorporating alloying materials in the electrode coating. The fluxing action of the slag will also produce weld metal of better quality and permit welding at higher speeds.

Tungsten Electrodes

Non-consumable welding electrodes for gas tungsten-arc (TIG) welding are of three types: pure tungsten, tungsten containing 1 or 2 percent thorium, and tungsten containing 0.3 to 0.5 percent zirconium.

Tungsten electrodes can be identified as to type by painted end marks as follows.

- Green – pure tungsten.

- Yellow – 1 percent thorium.

- Red – 2 percent thorium.

- Brown – 0.3 to 0.5 percent zirconium.

Pure tungsten (99. 5 percent tungsten) electrodes are generally used on less critical welding operations than the tungsten, which is alloyed. This type of electrode has a relatively low current-carrying capacity and a low resistance to contamination.

Thoriated tungsten electrodes (1 or 2 percent thorium) are superior to pure tungsten electrodes because of their higher electron output, better arc-starting and arc stability, high current-carrying capacity, longer life, and greater resistance to contamination.

Tungsten welding electrodes containing 0.3 to 0.5 percent zirconium generally fall between pure tungsten electrodes and thoriated tungsten electrodes in terms of performance. There is, however, some indication of better performance in certain types of welding using ac power.

Finer arc control can be obtained if the tungsten alloyed electrode is ground to a point (see figure 5-33). When electrodes are not grounded, they must be operated at a maximum current density to obtain reasonable arc stability. Tungsten electrode points are difficult to maintain if standard direct current equipment is used as a power source and touch-starting of the arc is standard practice. Maintenance of electrode shape and the reduction of tungsten inclusions in the weld can best be accomplished by superimposing a high-frequency current on the regular welding current. Tungsten electrodes alloyed with thorium and zirconium retain their shape longer when touch-starting is used.

The welding electrode extension beyond the gas cup is determined by the type of joint being welded. For example, an extension beyond the gas cup of 1/8 in. (3.2 mm) might be used for butt joints in light gage material, while an extension of approximately 1/4 to 1/2 in. (6.4 to 12.7 mm) might be necessary on some fillet welds. The tungsten electrode of the torch should be inclined slightly, and the filler metal added carefully to avoid contact with the tungsten. This will prevent contamination of the electrode. If contamination does occur, the electrode must be removed, reground, and replaced in the torch.

Direct Current Arc Welding Electrodes

The manufacturer’s recommendations should be followed when a specific type of welding electrode is being used. In general, direct current shielded arc electrodes are designed either for reverse polarity (electrode positive) or for straight polarity (electrode negative), or both. Many, but not all, of the direct current electrodes, can be used with alternating current. Direct current is preferred for many types of covered, nonferrous, bare, and alloy steel electrodes. Recommendations from the manufacturer also include the type of base metal for which given electrodes are suited, corrections for poor fit-ups, and other specific conditions.

In most cases, straight polarity electrodes will provide less penetration than reverse polarity electrodes, and for this reason, will permit greater welding speed. Good penetration can be obtained from either type with proper welding conditions and arc manipulation.

Alternating Current Arc Welding Electrodes

Coated electrodes which can be used with either direct or alternating current are available. Alternating current is more desirable while welding in restricted areas or when using the high currents required for thick sections because it reduces arc blow. Arc blow causes blowholes, slag inclusions, and lack of fusion in the weld.

An alternating current is used in atomic hydrogen welding and in those carbon arc processes that require two carbon electrodes. It permits a uniform rate of welding and electrode consumption. In carbon-arc processes where one carbon electrode is used, direct current straight polarity is recommended because the electrode will be consumed at a lower rate.

Electrode Defects & Their Effects

If certain elements or oxides are present in electrode coatings, the arc stability will be affected. In bare electrodes, the composition and uniformity of the wire is an important factor in the control of arc stability. Thin or heavy coatings on the electrodes will riot completely remove the effects of defective wire.

Aluminum or aluminum oxide (even when present in 0.01 percent), silicon, silicon dioxide, and iron sulfate unstable. Iron oxide, manganese oxide, calcium oxide, and stabilize the arc.

When phosphorus or sulfur is present in the electrode more than 0.04 percent, they will impair the weld metal because they are transferred from the electrode to the molten metal with very little loss. Phosphorus causes grain growth, brittleness, and “cold shortness” (i. e., brittle when below red heat) in the weld. These defects increase in magnitude as the carbon content of the steel increases. The sulfur acts as a slag, breaks up the soundness of the weld metal, and causes “hot shortness” (i. e., brittle when above red heat). Sulfur is particularly harmful to bare low-carbon steel electrodes with a low manganese content. Manganese promotes the formation of sound welds.

If the heat treatment, given the wire core of an electrode, is not uniform, the electrode will produce welds inferior to those produced with an electrode of the same composition that has been properly heat treated.

Deposition Rates

The different types of electrodes have different deposition rates due to the composition of the coating. The electrodes containing iron powder in the coating have the highest deposition rates. In the United States, the percentage of iron power in a coating is 10 to 50 percent. This is based on the amount of iron powder in the coating versus the coating weight. This is shown in the formula:

These percentages are related to the requirements of the American Welding Society (AWS) specifications. The European method of specifying iron power is based on the weight of deposited weld metal versus the weight of the bare core wire consumed. This is shown as follows:

Thus, if the weight of the deposit were double the weight of the core wire, it would indicate a 200 percent deposition efficiency, even though the amount of the iron powder in the coating represented only half of the total deposit. The 30 percent iron power formula used in the United States would produce a 100 to 110 percent deposition efficiency using the European formula. The 50 percent iron power electrode figured on United States standards would produce efficiency of approximately 150 percent using the European formula.

Non-consumable Electrodes

Types

There are two types of non-consumable welding electrodes.

- The carbon electrode is a non-filler metal electrode used in arc welding or cutting, consisting of a carbon graphite rod that may or may not be coated with copper or other coatings.

- The tungsten electrode is defined as a non-filler metal electrode used in arc welding or cutting, made principally of tungsten.

Carbon Electrodes

The American Welding Society does not provide specifications for carbon welding electrodes, but there is a military specification, no. MIL-E-17777C, entitled, “Electrodes Cutting and Welding Carbon-Graphite Uncoated and Copper Coated.”

This specification provides a classification system based on three grades: plain, uncoated, and copper coated. It provides diameter information, length information, and requirements for size tolerances, quality assurance, sampling, and various tests. Applications include carbon arc welding, twin carbon arc welding, carbon-cutting, and air carbon arc cutting and gouging.

Stick Electrodes

Stick welding electrodes vary by:

- Size: common rod sizes are 1⁄16, 5⁄64, 3⁄32 (most common), 1⁄8, 3⁄16, 7⁄32, 1⁄4, and 5⁄16 inches. Core wire used with electrodes needs to be narrower than the materials that are welded.

- Material: stick welding electrodes come in cast iron, high carbon steel, mild steel, iron-free (nonferrous), and special alloys.)

- Strength: referred to as tensile strength. Each weld needs to be stronger than the metal being welded. This means that the materials in the electrode need to be stronger as well.

- Welding position (horizontal, flat, etc.): different electrodes are used for each welding position.

- Iron powder mix (up to 60% in flux): iron powder in the flux increases the amount of molten metal available for the weld (heat turns the powder into steel).

- Soft arc designation: for thinner metals or metals that don’t have a perfect fit or gap.

As described above, there are many kinds of electrodes. Here are the most popular stick welding (SMAW) electrodes:

- E6013 and E6012: For thin metals and joints that do not easily fit together.

- E6011: Good for working on surfaces that are oily, rusted, or has dirt. Versatile in that it works with DC or AC polarity. Creates little slag, another big plus. Note that this electrode should not be placed into an electrode oven.

- E6010: Similar to the E6011 but only works with direct current (DC). Note that this electrode should not be placed into an electrode oven.

- E76018 and E7016: Manufactured with iron powder in the flux. It creates strong welds but has a puddle that might present some control issues for beginners.

Can cast iron and steel be welded ? And if so what welding rod is needed ?

For C I to weld together with SS most suitable is ENI CI

nickel rod should do the trick

I inherited some old electrodes without any numbers, but do have paint dots on the end. Black on the tip with a yellow dot on the bare part. And then some with a yellow dot on the bar part. Any idea what these might be?